Vertical Balers

From vertical to horizontal baler machines, PACKENER offers solutions for packaging, recycling, and waste management. Helping to cut costs, enhance efficiency, and drive sustainability across various industries.

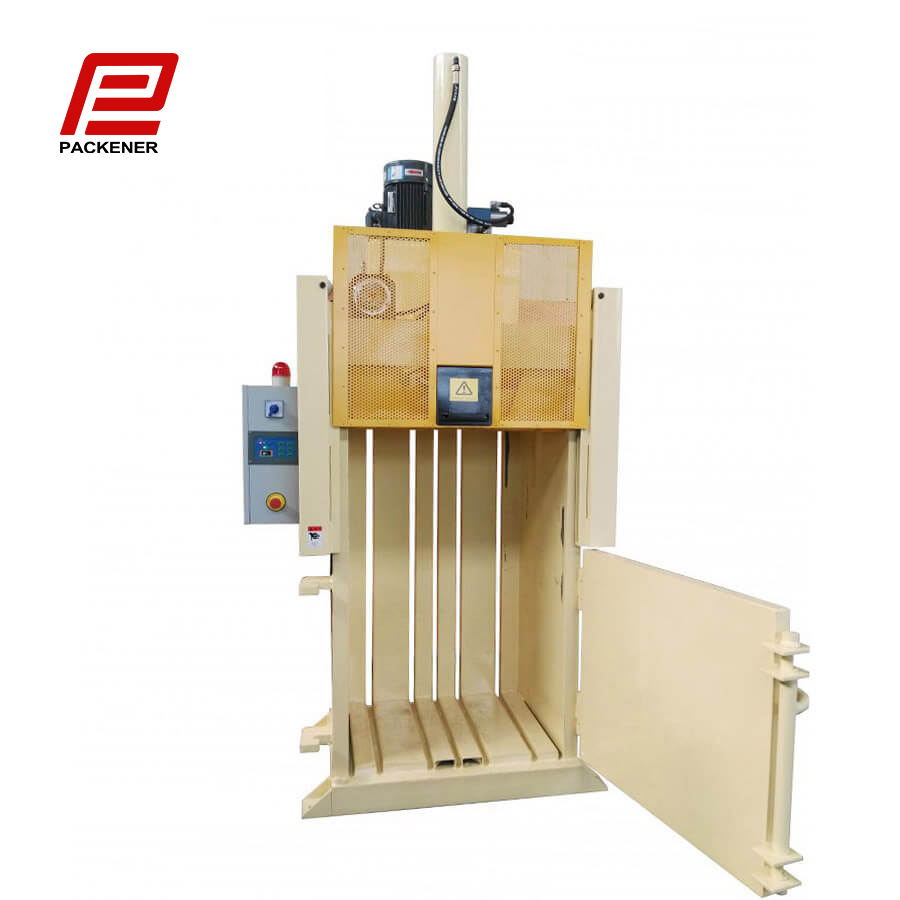

Textile Clothes Baling Machine For Sale

The Textile Clothes Baling Machine is a vital tool for managing textile waste efficiently. By compressing loose textiles into dense bales, it reduces storage and transportation costs, facilitates recycling, and promotes environmental sustainability. Its r

Information

- Category: Vertical Balers

- Release date: 2024-10-22 10:08:46

- Categories: Vertical Balers | Horizontal Balers | Automatic Baler Machines | Semi Automatic Balers | Scrap Metal Baler Machines | Small Baling Machine |

- URL: https://hydraulicbalers.com/vertical-balers/59.html

Richup's balers excel in waste compaction, catering to industries ranging from manufacturing to recycling. With customizable solutions, we tailor our balers to meet your specific needs. Plus, our comprehensive services ensure your baler operates at peak efficiency.

Ready to optimize your waste management process? Please leave a message online or call us now for a quote tailored to your requirements!

The Textile clothes baling machine is an advanced solution designed to compress textile materials, such as clothes, fabrics, and other related items, into dense, manageable bales. This machine is crucial for textile recycling centers, second-hand clothing businesses, and waste management facilities. It helps streamline the handling and transportation of textile waste, promoting efficient recycling and waste reduction.

Operation Process

Loading

Manual or Conveyor Loading: Textiles are either manually loaded or fed into the baler via a conveyor system.

Preparation: Ensure that the materials are free from non-textile contaminants to prevent damage to the machine and ensure efficient baling.

Compression

Starting the Machine: Using the control panel, start the baling cycle. The automated system takes over from here.

Hydraulic Compression: The hydraulic system activates, pressing the materials into a compact bale. The pressure applied is adjustable based on the type and volume of textiles being baled.

Monitoring: Operators can monitor the process through the control panel interface, ensuring the cycle runs smoothly.

Bale Formation

Density and Size Control: The machine compresses the textiles to a predetermined size and density, ensuring uniform bales.

Bale Strapping: Some machines automatically strap the bales to maintain their shape during storage and transportation. If not automatic, manual strapping may be required.

Ejecting

Automatic Ejection: Once the compression cycle is complete, the machine automatically ejects the finished bale.

Manual Removal: In some models, manual removal of the bale may be necessary, depending on the design and automation level of the machine.

Repeat Process

Continuous Operation: The machine is designed for continuous operation, allowing for the next load of textiles to be baled immediately after one cycle is complete.

Maintenance Check: Regularly check and maintain the machine as recommended by the manufacturer to ensure optimal performance and longevity.

Our team are available, connect now to talk about your requirements and get all your questions answered.

At PACKENER website , we understand the importance of privacy and security when it comes to handling your personal information. Rest assured that any information you provide through our message form is treated with the utmost confidentiality and care.

We employ robust security measures to safeguard your data from unauthorized access, disclosure, or misuse.

Your trust is paramount to us, and we are committed to protecting your privacy every step of the way. Your confidence in leaving messages with us allows us to better serve you and ensure a seamless experience with our services.