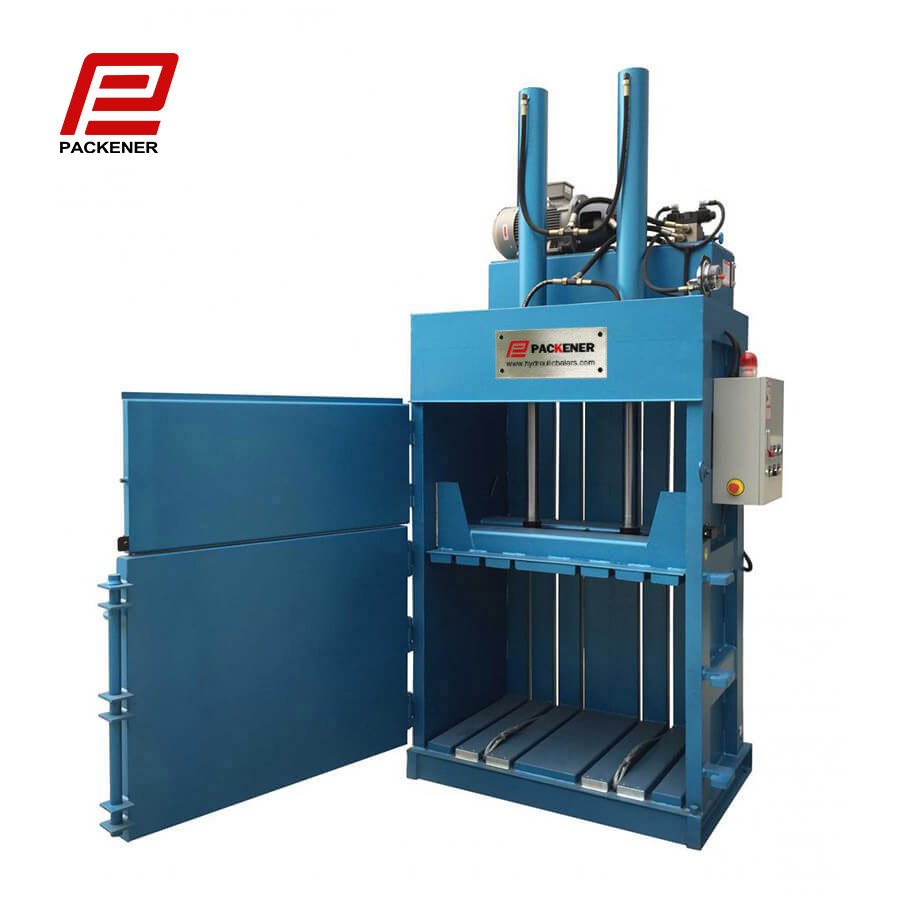

Vertical Balers

From vertical to horizontal baler machines, PACKENER offers solutions for packaging, recycling, and waste management. Helping to cut costs, enhance efficiency, and drive sustainability across various industries.

Plastic Bottle Baler Machine

The Plastic Bottle Baler Machine is a specialized piece of equipment designed to compress plastic bottles into compact, manageable bales. This machine is essential for recycling centers, waste management facilities, and businesses dealing with large volum

Information

- Category: Vertical Balers

- Release date: 2024-06-26 22:10:27

- Categories: Vertical Balers | Horizontal Balers | Automatic Baler Machines | Semi Automatic Balers | Scrap Metal Baler Machines | Small Baling Machine |

- URL: https://hydraulicbalers.com/vertical-balers/58.html

Richup's balers excel in waste compaction, catering to industries ranging from manufacturing to recycling. With customizable solutions, we tailor our balers to meet your specific needs. Plus, our comprehensive services ensure your baler operates at peak efficiency.

Ready to optimize your waste management process? Please leave a message online or call us now for a quote tailored to your requirements!

How baler machines Work?

To begin the process, soft or hard waste is loaded into the baler machine. The material is fed through a hopper and tin pan linked to a hydraulic ram. The hydraulic ram is contained by a steel frame and driven by an electric motor pump. The electric pump pressurizes fluid inside the hydraulic cylinder to generate the required compression force. The ram compresses the material into a small, uniform block.

The bale chamber determines the bale's shape before it’s ejected. Before or during ejection, the bales are tied with galvanized or black annealed wire to keep their shape. Then the ejection ram removes the material and any uncompressed material from the machine.

Balers have sturdy steel frames and an intentionally designed structure to ensure a long life with minimal maintenance. Balers are often designed with anti-wear steel plates for support, properly fitted main rams to reduce physical wear, and shearing tools to distribute stress evenly throughout the unit. High-performance balers use precision parts to eliminate misalignment and premature wear.

Test Methods for scrap metal balers

Ensuring the performance, reliability, and safety of scrap metal balers is critical. Here are several key test methods commonly employed to evaluate baler machines:

1. Compression Force Test

Objective: Measure the maximum compression force exerted by the hydraulic system.

Method: Use a load cell or pressure transducer to measure the force applied during a baling cycle. Ensure the machine operates at its specified capacity and verify the force readings against the manufacturer’s specifications.

Criteria: The measured force should match or exceed the specified compression force range (e.g., 80 tons to 200 tons).

2. Cycle Time Test

Objective: Determine the time taken to complete one full baling cycle.

Method: Use a stopwatch to measure the time from the start of the loading process to the completion of the bale ejection. Conduct multiple tests to obtain an average cycle time.

Criteria: The cycle time should fall within the specified range (e.g., 45-90 seconds per bale).

3. Bale Density and Size Test

Objective: Verify the density and dimensions of the bales produced.

Method: Measure the dimensions (length, width, height) of a finished bale and weigh it. Calculate the bale density using the formula: Density = Weight / Volume.

Criteria: The bale size and density should meet the specified parameters (e.g., 1000mm x 800mm x 600mm, 250-700 kg, density 400-800 kg/m³).

At PACKENER website , we understand the importance of privacy and security when it comes to handling your personal information. Rest assured that any information you provide through our message form is treated with the utmost confidentiality and care.

We employ robust security measures to safeguard your data from unauthorized access, disclosure, or misuse.

Your trust is paramount to us, and we are committed to protecting your privacy every step of the way. Your confidence in leaving messages with us allows us to better serve you and ensure a seamless experience with our services.