Semi Automatic Balers

From vertical to horizontal baler machines, PACKENER offers solutions for packaging, recycling, and waste management. Helping to cut costs, enhance efficiency, and drive sustainability across various industries.

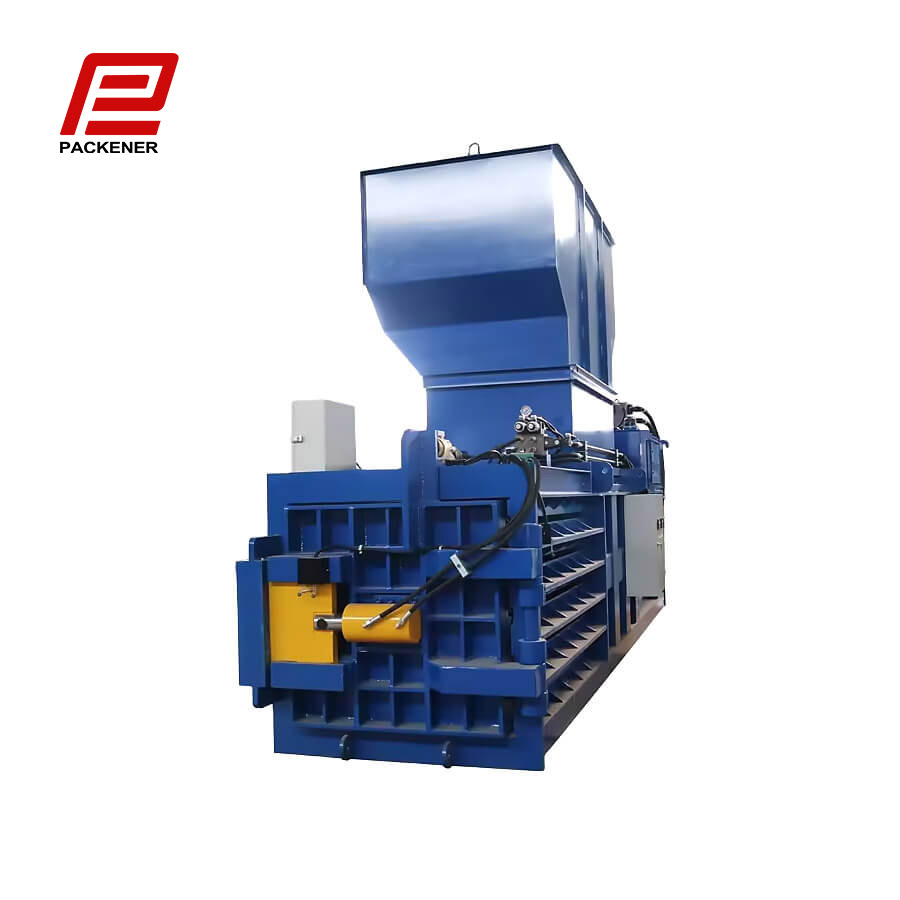

Semi-Automatic Cardboard PET Bottle Baling Machine

The Semi-Automatic Cardboard PET Bottle Baling Machine is ideal for beverage manufacturers, recycling centers, and any other industries that generate large quantities of cardboard PET bottle waste.

Information

- Category: Semi Automatic Balers

- Release date: 2024-06-30 15:08:04

- Categories: Vertical Balers | Horizontal Balers | Automatic Baler Machines | Semi Automatic Balers | Scrap Metal Baler Machines | Small Baling Machine |

- URL: https://hydraulicbalers.com/semi-automatic-balers/83.html

Richup's balers excel in waste compaction, catering to industries ranging from manufacturing to recycling. With customizable solutions, we tailor our balers to meet your specific needs. Plus, our comprehensive services ensure your baler operates at peak efficiency.

Ready to optimize your waste management process? Please leave a message online or call us now for a quote tailored to your requirements!

Operational Procedure for Semi-Automatic Cardboard pet bottle baling machine

1. Preparation

Ensure the machine is in a clean and dry environment.

Check the power supply and ensure it meets the machine's requirements.

Inspect the machine for any loose parts, damaged components, or obstructions in the work area.

Verify the availability of necessary tools, consumables, and safety equipment.

2. Startup

Switch on the main power supply and turn on the machine's control panel.

Perform a safety check to ensure all sensors and safety mechanisms are functioning properly.

Adjust the settings on the control panel according to the type and size of the cardboard PET bottles to be baled.

3. Loading Material

Load the cardboard PET bottles into the feeding inlet of the machine.

Ensure the bottles are evenly distributed and not overloaded.

Monitor the feeding process and adjust the feeding rate if necessary.

4. Baling Process

Start the baling process by activating the relevant controls on the machine's control panel.

The machine will compress and bundle the bottles into a bale.

Monitor the baling process and ensure the bale is being formed properly.

5. Bale Removal

Once the bale is formed, stop the baling process.

Open the bale outlet and carefully remove the bale from the machine.

Ensure the bale is handled safely and transported to the desired location.

6. Cleanup and Maintenance

Clean the machine's interior and exterior, removing any residue or debris.

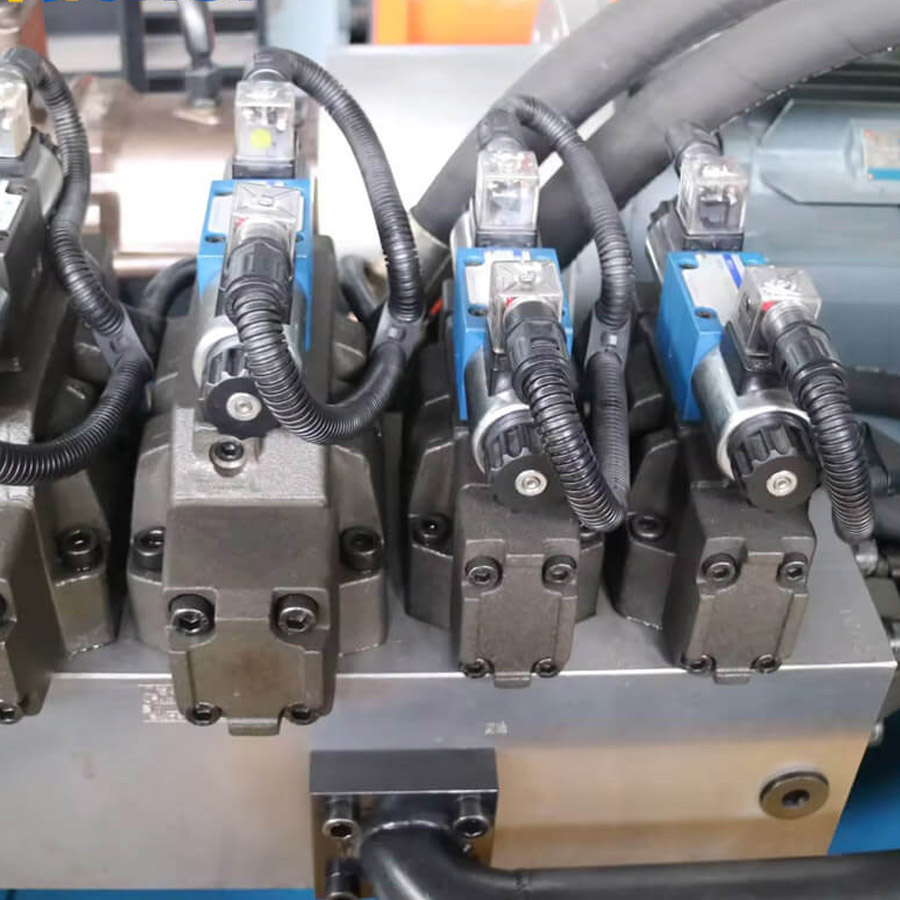

Perform routine maintenance checks, such as lubricating moving parts and checking belts and pulleys.

Inspect the machine for any wear or damage and replace any worn-out parts if necessary.

7. Shutdown

Turn off the machine's control panel and main power supply.

Ensure all moving parts have stopped and the machine is in a safe condition.

Store the machine in a dry and protected area to prevent damage or corrosion.

Why Choose RICHUP Machine?

With our commitment to quality and innovation, we ensure that our Semi-Automatic baler( Cardboard PET Bottle baling machine) is built to last. Our team of experts provides comprehensive support and after-sales service, ensuring you get the most out of your investment. Choose our machine and experience the difference in waste management and recycling efficiency.

At PACKENER website , we understand the importance of privacy and security when it comes to handling your personal information. Rest assured that any information you provide through our message form is treated with the utmost confidentiality and care.

We employ robust security measures to safeguard your data from unauthorized access, disclosure, or misuse.

Your trust is paramount to us, and we are committed to protecting your privacy every step of the way. Your confidence in leaving messages with us allows us to better serve you and ensure a seamless experience with our services.